Thermoforming

What is thermoforming technology?

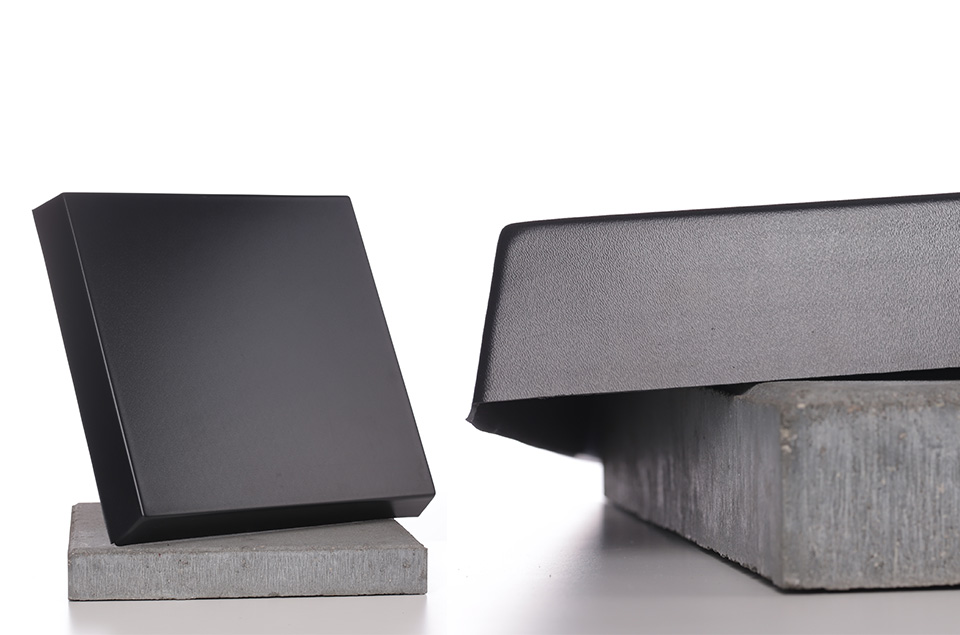

Thermoforming involves obtaining a specific shape from plastics. The plastics are heated to temperatures at which they become malleable and mouldable. Then appropriately shaped dies give them the desired appearance. Thanks to this technology, we are able to produce any detail and meet the most demanding projects.

Benefits and applications of thermoforming.

Thermoforming is a very attractive solution for advertising. This is supported by the visual appeal of the products and the relatively low production costs. It is an excellent alternative to expensive injection moulding technology. We use thermoforming to produce advertising materials, as well as parts such as casings, mouldings and packaging for other industries.